- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Blog

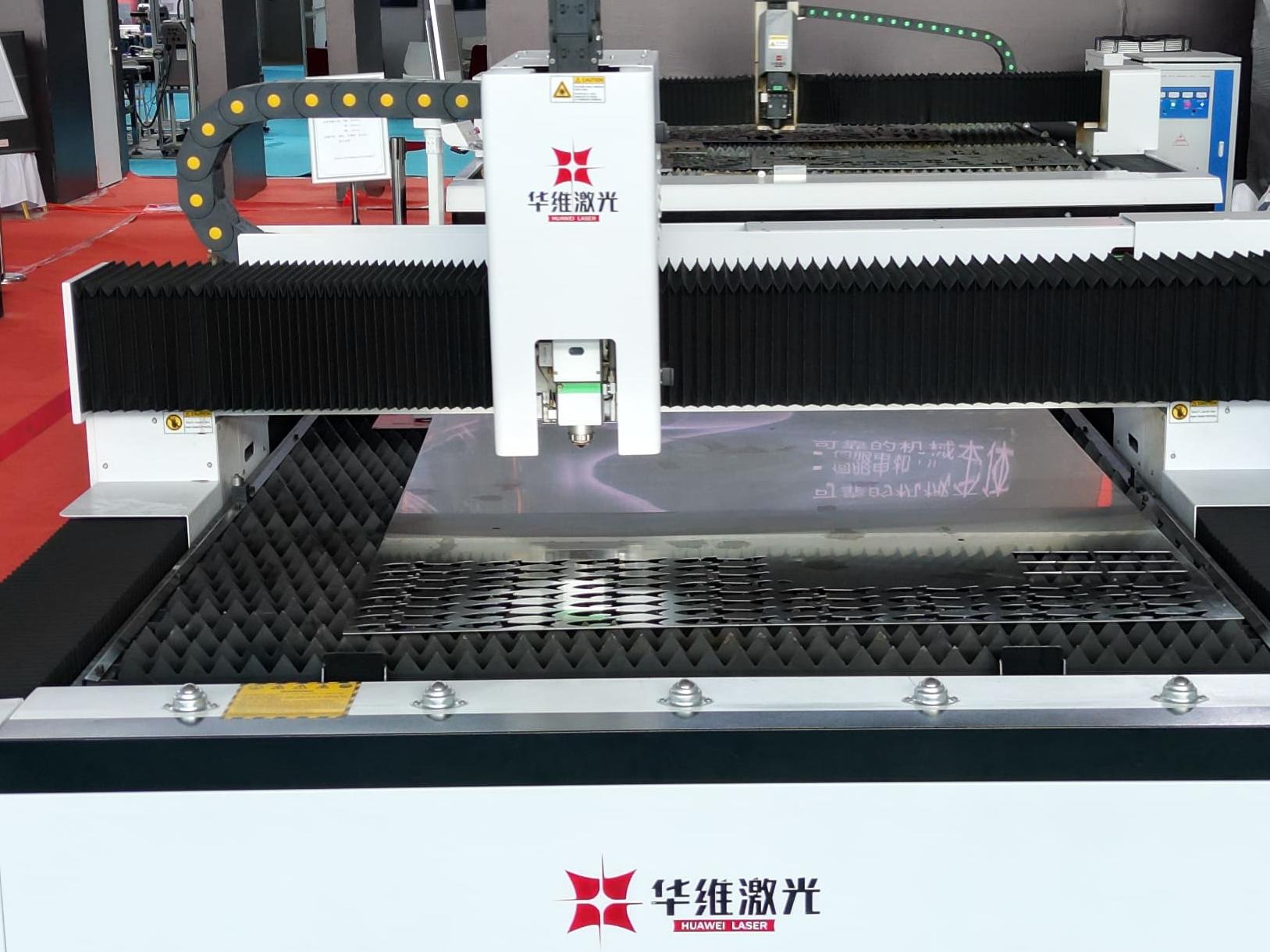

Requirements for the Use Environment of Laser Cutting Machines

Laser cutting machines require a stable environment for optimal performance. Factors like temperature, humidity, and power stability affect precision and efficiency. Maintaining ideal conditions minimizes failures, reduces costs, and extends service life.

Read MoreCan Laser Cutting Machines Handle Galvanized Sheet, Copper, and Aluminum Materials?

Due to their high reflectivity and thermal conductivity, traditional laser cutting of highly reflective materials such as galvanized sheets, copper, and aluminum presents certain challenges, such as laser reflection damaging equipment and unstable cutting. However, with the continuous advancement of......

Read MoreKey Considerations for Laser Cutting Machines in Cutting Complex Shapes

With the widespread application of laser cutting technology, companies need to pay attention to the following key issues when processing complex shapes or curved materials to ensure cutting quality and production efficiency.

Read MoreFiber Laser Cutting Machine Operating Cost Analysis

This article will analyze the operating costs of fiber laser cutting machines from the aspects of power consumption, auxiliary gas, consumables and labor costs, and explore optimization strategies to help companies improve efficiency and reduce expenses.

Read MoreWhat Affects the Cutting Speed of Laser Cutting Machines?

The cutting speed of laser cutting machines directly affects production efficiency and cost control. The cutting speed is determined by a variety of factors, including equipment performance, material properties, process parameters, and external environment. By upgrading high-power equipment, optimiz......

Read MoreWhy Laser Pipe Cutting is Overtaking Traditional Technique?

Traditional methods such as mechanical sawing, plasma cutting and flame cutting have obvious limitations in accuracy, efficiency and flexibility. As a modern process, laser tube cutting technology has quickly emerged with its outstanding advantages of high precision, high efficiency and environment......

Read More