- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

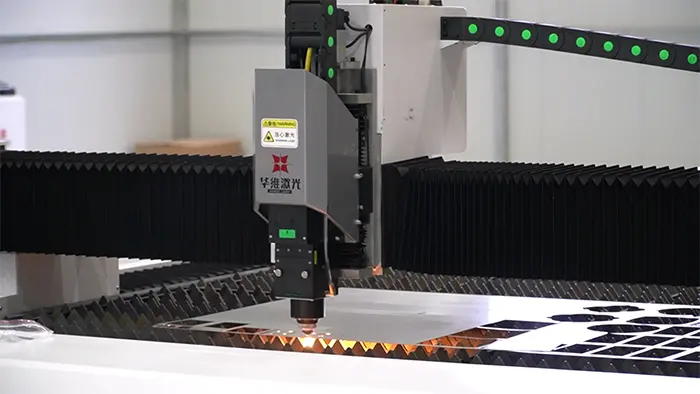

What Affects the Cutting Speed of Laser Cutting Machines?

2025-02-05

The cutting speed of laser cutting machines directly affects production efficiency and cost control. The cutting speed is determined by a variety of factors, including equipment performance, material properties, process parameters, and external environment. By upgrading high-power equipment, optimizing process parameters, strengthening equipment maintenance, improving environmental conditions, and introducing intelligent technology, the cutting speed and production efficiency of the cutting machine can be significantly improved.

1. The main factors affecting cutting speed

Equipment performance

Equipment performance is the core factor that determines the cutting speed. High-power lasers can provide stronger energy output, thereby significantly improving cutting efficiency. At the same time, the precise control system of the CNC cutting machine can optimize the cutting path and reduce time waste. The stability and operating status of the equipment will also affect the continuous speed and quality of cutting.

Material properties

The properties of the material being cut directly affect the cutting speed. Materials with high hardness and high density (such as stainless steel and titanium alloy) usually require lower cutting speeds to ensure edge quality. Materials with good thermal conductivity such as carbon steel can be cut at a faster speed. In addition, highly reflective materials (such as aluminum and copper) have low laser absorption efficiency, which will also limit the cutting speed.

Process parameters

The setting of cutting process parameters plays a key role in speed. Parameters such as laser power, cutting head movement speed, auxiliary gas selection and pressure will affect cutting efficiency. For example, increasing laser power or reasonably selecting auxiliary gas (such as oxygen) can significantly speed up cutting speed, but a balance needs to be found between efficiency and quality.

External environment

Environmental conditions such as temperature, humidity and equipment maintenance status will also affect cutting efficiency. If the optical lens of the equipment is contaminated or the optical path is not accurately calibrated, the laser energy will be attenuated, thereby reducing the cutting speed.

2. Effective methods to increase cutting speed

The cutting speed of the cutting machine can be improved in many ways, including upgrading high-power laser equipment, using autofocus cutting heads, optimizing process parameters (such as laser power, cutting speed and auxiliary gas selection), regularly maintaining equipment to ensure the cleanliness of the optical system, improving workshop environmental conditions (such as controlling temperature and humidity and reducing dust), and introducing intelligent technology to realize automated production lines and dynamic process adjustments. These comprehensive measures can significantly improve cutting efficiency and meet the high-efficiency needs of industrial production.