- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Blog

Why Laser Pipe Cutting is Overtaking Traditional Technique?

Traditional methods such as mechanical sawing, plasma cutting and flame cutting have obvious limitations in accuracy, efficiency and flexibility. As a modern process, laser tube cutting technology has quickly emerged with its outstanding advantages of high precision, high efficiency and environment......

Read MoreProlonging Performance: Daily Maintenance Tips for Laser Cutting Machines

If you have just purchased a laser cutting machine, but you are not familiar with the daily maintenance process of the equipment, don't worry. The following are the key points of daily care and maintenance of laser cutting machines. Through standardized operation and scientific maintenance methods, ......

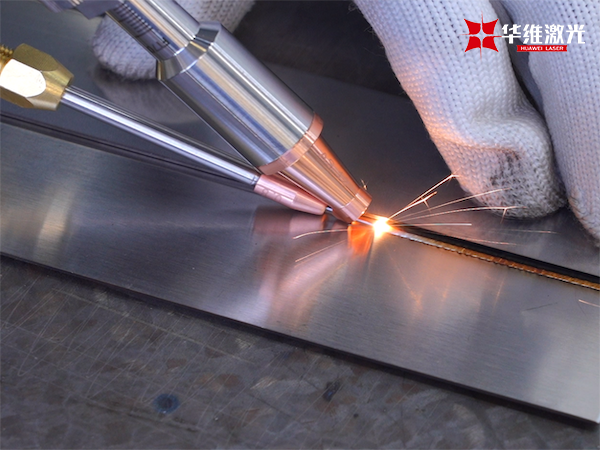

Read MoreUnderstanding Wire Feeding in Laser Welding

Wire feeding technology in laser welding is a key component for achieving high-quality welding. By reasonably selecting wire material, diameter, wire feeding method and accurately controlling wire feeding speed, welding efficiency and joint quality can be effectively improved. The following details ......

Read MoreIs Your Air - Cooled Laser Welder a Safety Risk? Find Out

With the continuous development of welding technology, the safety of air-cooled handheld welding machines has become the focus of industry attention. Sometimes leakage, overheating, and other phenomena may occur. However, the air-cooled welding machine series launched by Huawei Laser inherits ten co......

Read MoreLaser Cutting Equipment Safe Operation Instructions

Laser cutting technology is widely used in industrial processing due to its high precision and high efficiency. However, the high energy output and complex operation of laser equipment also bring certain safety hazards. In order to ensure the safety of personnel and the stable operation of equipment......

Read MoreIn What Scenarios Can Air-Cooled Handheld Laser Welding be Used?

Air-cooled welding machines are widely used in small and medium-sized production lines, temporary operations and scenarios with high environmental protection requirements due to their high efficiency, energy saving and no need for water cooling systems. They improve production efficiency, reduce cos......

Read More