- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Why We Choose Handheld Laser Welding Machine over Argon Arc Welding

2025-12-23

Why We Choose Handheld Laser Welding Machine over Argon Arc Welding

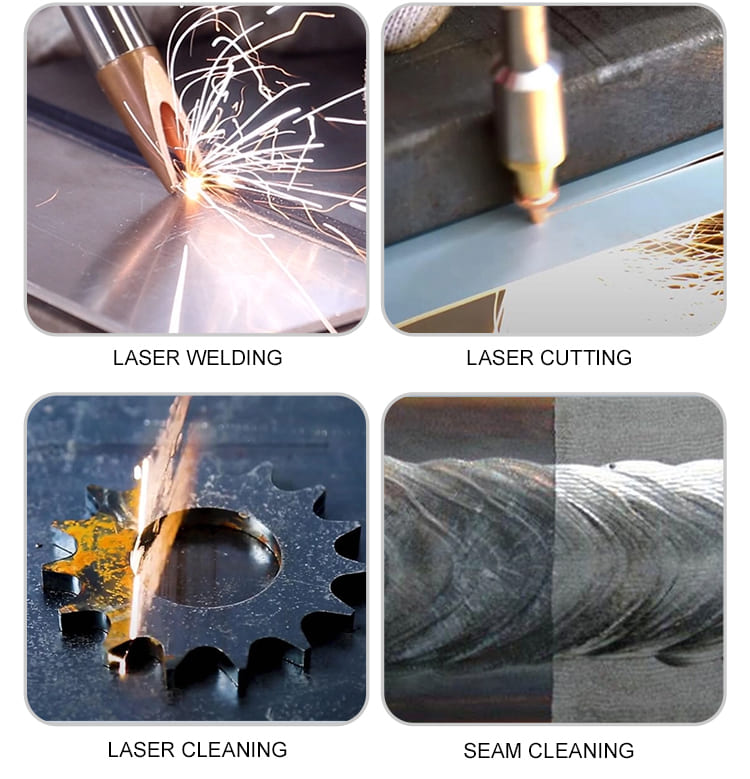

At HUAWEI LASER, we specialize in cutting-edge welding technologies designed to meet the evolving needs of modern industries. In this article, we’ll explore why the Handheld Laser Welding Machine is a superior choice compared to the traditional Argon Arc Welding method.

1. Precision and Accuracy

The Handheld Laser Welding Machine delivers high-precision welds with minimal heat distortion. Unlike Argon Arc Welding, which can sometimes result in uneven heat distribution, the laser welding process provides a clean and accurate finish, making it ideal for delicate materials and complex geometries.

2. Speed and Efficiency

One of the biggest advantages of the Handheld Laser Welding Machine is its speed. Laser welding allows for faster welding times with greater control, making it ideal for high-volume production. In contrast, Argon Arc Welding tends to be slower and often requires additional steps for post-welding cleaning and finishing.

3. Reduced Heat Affected Zone (HAZ)

The Handheld Laser Welding Machine generates less heat during the welding process, resulting in a smaller Heat Affected Zone (HAZ). This is particularly beneficial when working with thin or heat-sensitive materials. Argon Arc Welding, on the other hand, tends to produce a larger HAZ, which can lead to warping or material degradation.

4. Minimal Post-Welding Work

With the Handheld Laser Welding Machine, there is less need for post-weld finishing. The laser process typically results in smoother welds, reducing the need for grinding, polishing, or additional treatments. This not only saves time but also cuts down on material waste and labor costs, providing a more efficient solution.

5. Portability and Flexibility

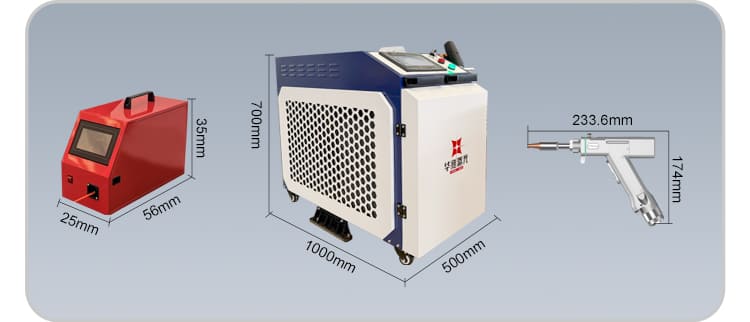

The Handheld Laser Welding Machine is highly portable, offering the flexibility to weld in a variety of locations and settings. Whether it's in a factory, on-site, or in a workshop, the handheld design allows operators to move freely and perform precise welds in difficult-to-reach areas. Argon Arc Welding, in comparison, requires bulky equipment and is less versatile.

6. Environmentally Friendly

Laser welding is also a more environmentally friendly choice. It produces less smoke and fumes compared to traditional welding methods like Argon Arc Welding, which can be harmful to both operators and the environment. The Handheld Laser Welding Machine helps create a cleaner work environment and reduces the need for protective equipment, making it a safer choice.

At HUAWEI LASER, we are dedicated to offering innovative welding solutions like the Handheld Laser Welding Machine that are not only efficient but also cost-effective. Our advanced products are backed by strong after-sales support to ensure that our clients experience maximum satisfaction and success in their welding projects.

For more information, visit our website at HUAWEI LASER to explore our full range of products and learn how our laser welding technology can benefit your business.