- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Why does an Open Type Fiber Laser Cutting Machine help my workshop win quick-turn business?

2025-12-15

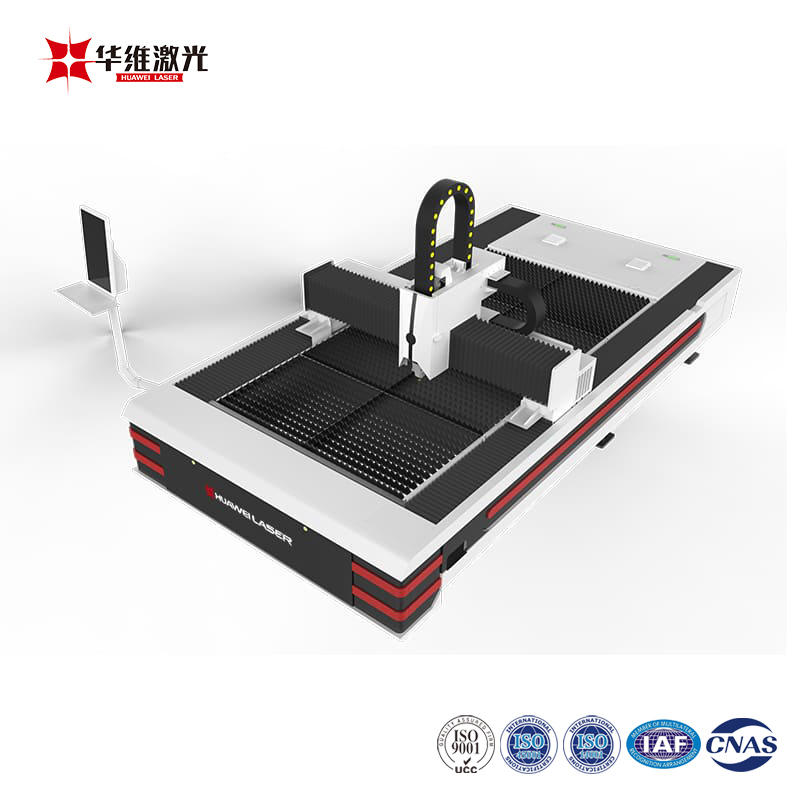

When I reworked my cutting workflow last year, I found myself comparing multiple vendors and kept returning to Huawei for one simple reason: the way an Open Type Fiber Laser Cutting Machine removes friction from day-to-day production. I needed cleaner edges on stainless and carbon steel, faster changeovers, and less hovering over the console. The open bed looked minimal, yet the throughput jump in short, mixed batches was hard to ignore.

What everyday problems does an Open Type Fiber Laser Cutting Machine actually solve?

- I load sheets from the side without door cycles, trimming dead time between nests.

- I swap jobs faster because jigs, remnants, and pierce behavior stay in clear view.

- I keep small-lot orders profitable; changeovers no longer devour margins.

- I train new operators quickly; open visibility shortens the learning curve.

How do I convert speed into real lead time and cash flow?

Customers pay for parts on time, not for meters per minute on a spec sheet. The open layout of an Open Type Fiber Laser Cutting Machine lets one operator stage the next sheet while the current cut finishes. Those seconds between jobs add up to earlier ship dates and tighter quotes.

| Workflow question | What I measure | Why it matters |

|---|---|---|

| Can I stage the next sheet while cutting? | Seconds between nests | Tiny gaps raise daily throughput without chasing higher power |

| How fast can I react to pierce or scrap issues? | Intervention time | Open access enables quick corrections and lower scrap |

| Do I recover and reuse remnants effectively? | Remnant recovery rate | Visible bed supports smarter nesting and lower material cost |

| Is edge quality consistent across shifts? | Post-process minutes per part | Clean edges mean less grinding and faster shipping |

Which materials and thicknesses benefit most and why?

- Carbon steel — predictable kerf and high speed on common gauges keep job-shop work moving.

- Stainless — stable gas control and optics preserve edge color and reduce deburr time.

- Aluminum — reliable anti-reflection protection in the head protects optics under reflective loads.

I right-size power to my actual mix. Overspec kilowatts raise utilities and optics wear. The open layout in an Open Type Fiber Laser Cutting Machine already removes downtime; matching power to parts locks in ROI.

What features do I prioritize before signing a purchase order?

- Rigid frame and drives for dimensional stability as the table warms.

- Servo quality and quick calibration to keep nests square to edges.

- Head protections—anti-collision, pierce control, capacitive sensing—to save nozzles and lenses.

- Gas management that controls edge tint and burrs on stainless.

- CAM nesting with true-shape algorithms and micro-tabs to tame small part tip-ups.

How do I keep an open table safe and compliant without killing productivity?

Open does not mean careless. I mark approach zones, apply guarded light curtains based on my risk assessment, and standardize approach sides. Current open-bed systems from Huawei pair fast sensors with clear sight lines, so I keep the agility that sold me on an Open Type Fiber Laser Cutting Machine while staying audit-ready.

Where do hidden costs live and how do I avoid them?

- Nozzles and lenses — I track life by material and stop “cheap parts” downtime.

- Assist gas — I tune nitrogen pressure on thin gauges to curb spend.

- Software — I budget for updates that improve yield, not just add menus.

- Operator fatigue — the open view helps, and sensible rotations keep quality steady.

Quarterly audits keep my Open Type Fiber Laser Cutting Machine predictable to own and steady to schedule.

Why did I shortlist Huawei when I compared vendors?

I wanted a production system, not just a cutter: stable sources, responsive service, and practical training. The Huawei ecosystem checked those boxes without forcing me into a bulky enclosure I did not need. With an Open Type Fiber Laser Cutting Machine, the standout feature turned out to be visibility—of the cut, the workflow, and the true cost per part.

What quick checklist keeps my trials honest?

- Does the bed support comfortable side loading with a cart or forklift?

- Can I adjust pierce strategies by material directly in CAM?

- Are nozzle swaps tool-less and repeatable under 60 seconds?

- Is there solid protection against reflected energy on aluminum?

- Do I get proven cut libraries rather than demo-only settings?

Run that list during trials and you will feel how an Open Type Fiber Laser Cutting Machine trims lead time without extra managerial overhead.

What results did I see after three months and would I do it again?

Setup gaps shrank, on-time performance climbed, and my quotes grew bolder because the schedule finally breathed. Operators liked the open view and took ownership of remnant reuse. For small and mid-size batches, the Open Type Fiber Laser Cutting Machine became the default choice, not a niche tool.

How do we talk next steps so you can test this on your parts?

If you want to validate edge quality, nesting efficiency, and true cycle times on your drawings, send a trial batch and let’s compare data. I am happy to walk through power sizing, gas recipes, and fixture tips for your mix. Ready to move fast with an Open Type Fiber Laser Cutting Machine on your line? Contact us today—share your DXF/DWG, target materials, and thicknesses, and we will reply with sample cuts and a clear ROI path. You can contact us now to start the trial and secure production capacity for your next project.