- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Advantages of Laser Cutting over Water Cutting

2025-12-23

Advantages of Laser Cutting over Water Cutting

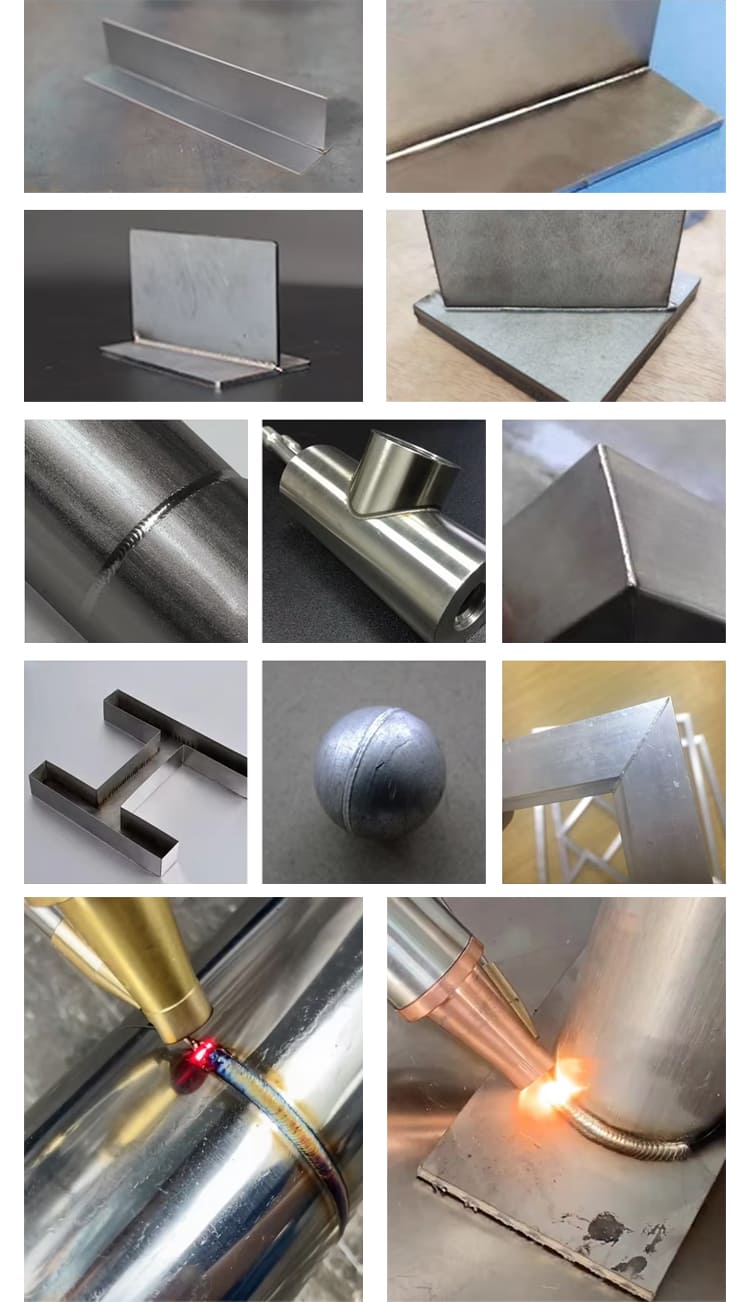

1. Higher Precision and Finer Cutting Lines

Laser cutting offers higher precision than water cutting. HUAWEI LASER's laser cutting technology provides extremely fine cutting results, ideal for precision manufacturing. While water cutting can be useful in certain situations, it produces rougher cutting lines that can result in uneven edges, especially when working with complex shapes and thin materials. In contrast, Handheld Laser Welding technology ensures each weld is precise and clear, greatly improving the quality of the final product.

2. Faster Cutting Speed

Handheld Laser Welding and laser cutting are significantly faster than traditional water cutting. Water cutting typically requires longer processing times due to high-pressure water flow, while laser cutting uses a high-speed laser beam to cut materials quickly, dramatically improving production efficiency. For industries requiring high-volume production, HUAWEI LASER's laser cutting technology is undoubtedly a more competitive solution.

3. Smaller Heat Affected Zone (HAZ)

Laser cutting generates much less heat compared to water cutting, resulting in a smaller Heat Affected Zone (HAZ). HUAWEI LASER's laser cutting technology minimizes thermal impact, preventing damage to materials. This is particularly beneficial when working with thin or heat-sensitive materials. In contrast, water cutting tends to create a larger HAZ, which can lead to warping or degradation of materials.

4. Less Post-Welding Work

Another advantage of laser cutting is that it requires less post-processing. Unlike water cutting, which often requires extensive post-weld finishing such as grinding and deburring, Handheld Laser Welding typically produces smoother welds that require little to no additional processing. This not only saves time but also reduces material waste and labor costs. Using HUAWEI LASER's laser cutting technology can significantly improve overall efficiency on the production line.

5. More Environmentally Friendly

Laser cutting is also more environmentally friendly. Compared to the significant water and chemical usage in water cutting, laser cutting consumes less energy and does not produce the waste generated by water cutting. HUAWEI LASER focuses on sustainability, and its products comply with environmental regulations, reducing wastewater discharge and material waste. As environmental standards become more stringent, laser cutting is undoubtedly a more future-proof choice.

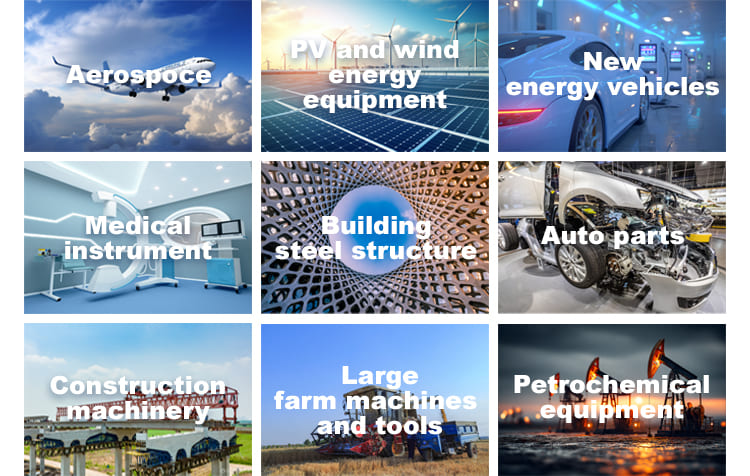

6. Versatility and Wide Application Range

Laser cutting can handle various metal and non-metal materials with ease. Handheld Laser Welding technology also plays a significant role in many sectors such as automotive manufacturing, electronics, and construction. In contrast, water cutting is more limited by material types and shapes and lacks the flexibility of laser cutting. HUAWEI LASER's technology meets the diverse needs of various industries, making it the ideal choice for manufacturers across different fields.

Conclusion

From the comparison above, it is clear that laser cutting has many advantages over water cutting, especially in terms of precision, speed, environmental impact, and post-processing. As an industry leader, HUAWEI LASER, with its advanced Handheld Laser Welding technology and robust after-sales service, helps businesses enhance production efficiency and product quality. If you're looking for an efficient laser cutting solution, visit HUAWEI LASER to learn more about our products.