- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Blog

Why Choose a Double-Chucks Tube Fiber Laser Cutting Machine for Your Business?

In modern metal processing industries, efficiency and precision have become essential requirements. The Double-Chucks Tube Fiber Laser Cutting Machine is designed to meet these needs by combining high-speed cutting performance with advanced control technology.

Read MoreDefinition and Working Principle of Sheet Metal Laser Cutting Machine

Speaking of metal processing, the coolest technology now is probably laser cutting. Just like Edward Scissorhands can cut out exquisite ice sculptures in the movie, laser cutting machines can also "cut" out various complex patterns on steel plates. However, it does not use scissors, but high-energy ......

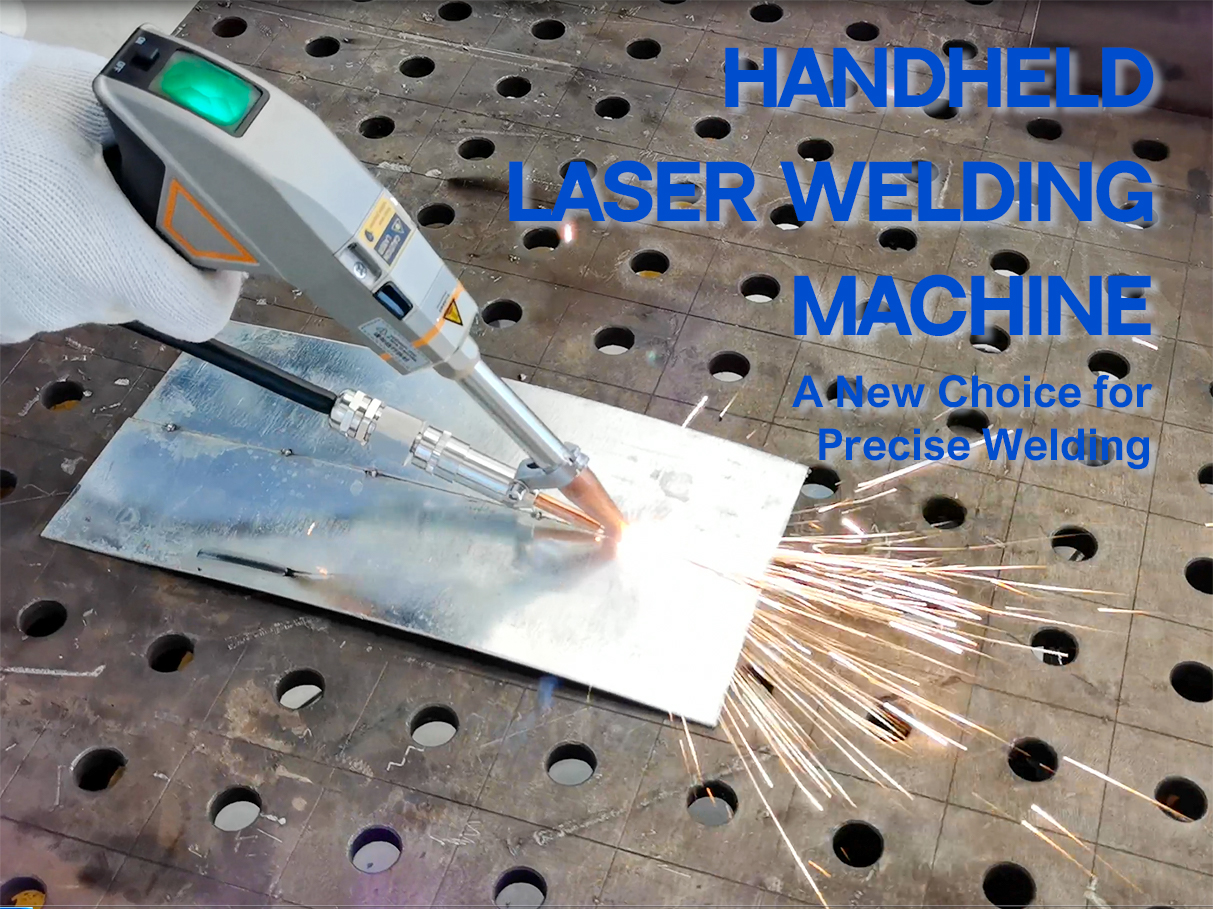

Read MoreHandheld Laser Welding Machine: A New Choice for Precise Welding

With the continuous improvement of welding accuracy and efficiency requirements in the manufacturing industry, traditional welding methods such as argon arc welding and electric welding have gradually exposed limitations such as complex operation, low efficiency, and significant thermal impact. Hand......

Read MoreLaser Cleaning: Redefining Industrial Cleaning

Laser cleaning is a method that uses a high-energy laser beam to irradiate the surface of an object, causing surface contaminants (such as oxides, oil, paint, rust, etc.) to rapidly absorb heat and evaporate or peel off. This process does not rely on chemical agents or contact-based abrasives. It of......

Read MoreKey Indicators of Laser Cutting Quality

In modern manufacturing, laser cutting technology is widely used in metal processing, automotive manufacturing, aerospace, and other industries due to its high precision and efficiency. However, evaluating the cutting quality of a laser cutting machine is a key concern for many businesses. The follo......

Read More