- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

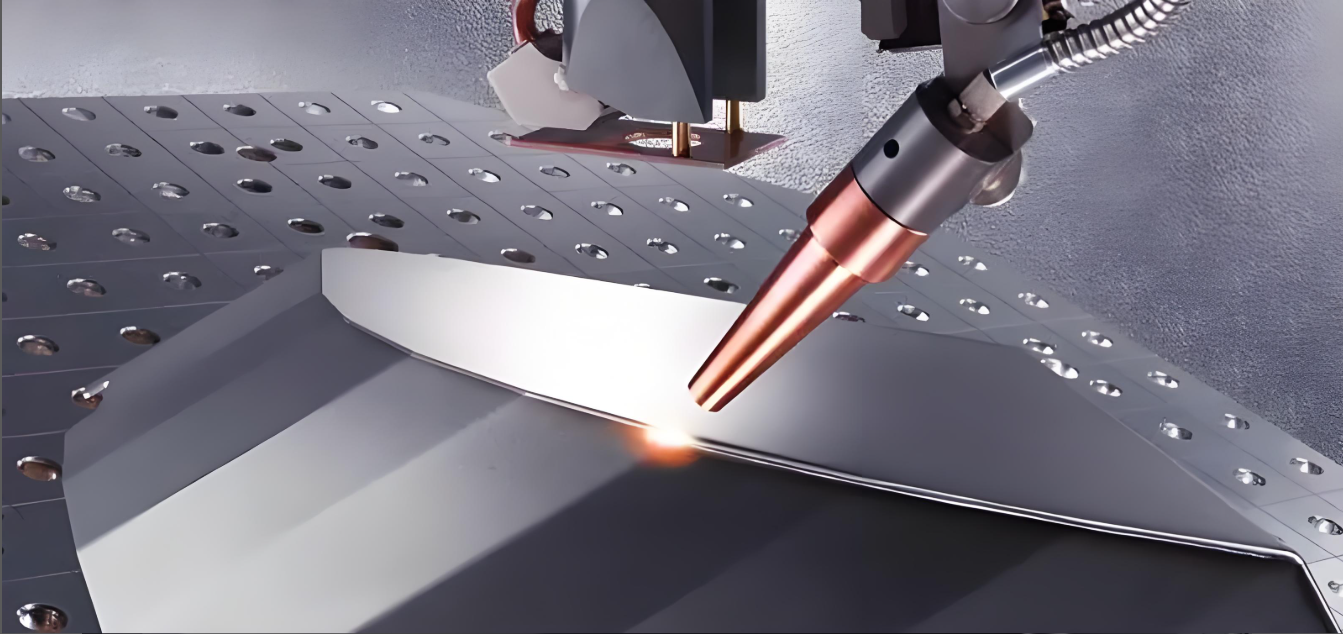

Advantages of Handheld Laser Welding Machine for Ultra-Thin Materials

2025-04-07

Compared to traditional welding methods, laser welding has become the ideal choice for processing ultra-thin materials due to its high energy density, precise control, and small heat-affected zone.

Laser welding works by focusing a laser beam to melt the material in a very short period, achieving efficient welding. The technology demonstrates the following advantages in ultra-thin material processing:

Small Heat-Affected Zone and Strong Control of Welding Deformation

Laser welding concentrates heat input, limiting the energy’s impact range and significantly reducing heat diffusion to surrounding areas. This minimizes welding deformation and stress concentration, preventing burn-through. It is especially suitable for heat-sensitive materials and complex structural components.

Small Weld Size and High Precision

Laser welding can precisely control the weld width, providing high weld strength and consistent joint quality, making it ideal for micro and precision component processing.

Non-Contact Processing and Easy Integration with Automation

Laser welding does not require direct contact with the workpiece, reducing equipment wear and tear. It can be integrated with automated production lines, such as robotic arms and vision systems, to meet high-efficiency production demands.

Wide Material Compatibility

Laser welding is compatible with a wide range of metal materials, including stainless steel, copper, aluminum, titanium alloys, and can achieve stable welding between dissimilar metals.

Strong Process Control to Meet High Standards

The process parameters of laser welding, such as power, frequency, and speed, can be precisely adjusted to meet the strictest welding quality requirements in various applications.

Huawei Laser focuses on the research and development of laser welding and cutting equipment, as well as intelligent robotic systems. Huawei Laser’s handheld laser welding machine offers ease of operation, high flexibility, and a broad application range, ideal for rapid welding of thin materials. It is widely used in industries such as stainless steel kitchenware, sheet metal processing, and signage. The equipment integrates advanced laser control technology and safety protection systems, supports quick material switching, and meets high-efficiency production needs.