- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

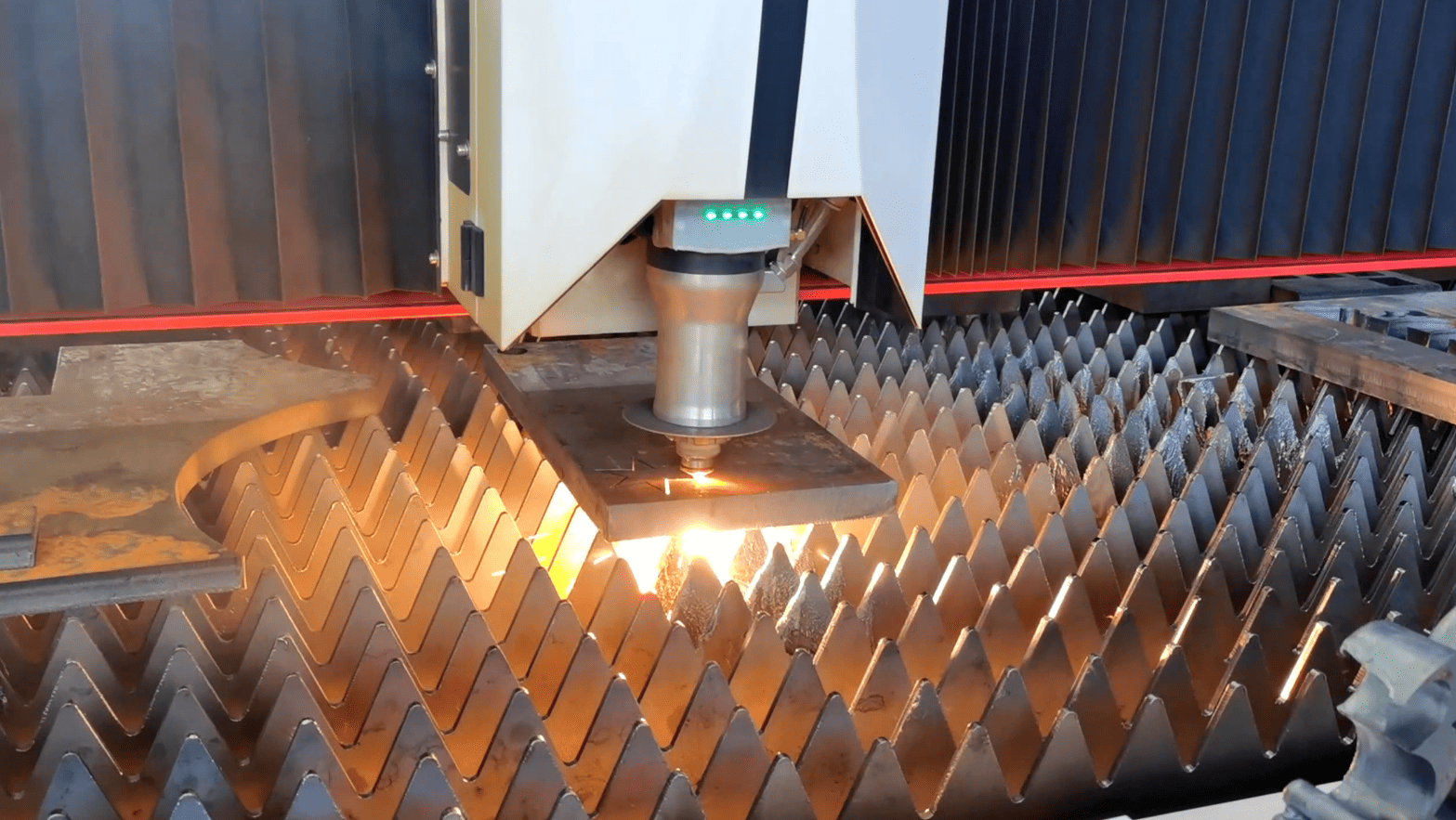

Analysis and Prevention of Sparks Emitted from Gas Nozzles During Cutting

Sparks have been emitted from gas nozzles during cutting in some industrial cutting operations, which not only affects the cutting quality but also poses a potential risk to safety. Experts believe that there are many reasons for sparks from gas nozzles, which can be summarized as follows:

1. Improper gas mixing ratio

During the gas cutting process, the mixing ratio of oxygen and fuel gas is crucial. If the ratio of oxygen and fuel gas is not properly adjusted, it may cause incomplete combustion or unstable flames, resulting in sparks. For example, too much oxygen may cause the fuel gas to burn too quickly and produce unstable flames; while too much fuel gas may cause incomplete flame combustion and produce larger sparks.

2. Blocked or worn nozzles

Nozzles are key components in gas cutting equipment. After long-term use, they may accumulate dirt or wear, affecting the normal flow of gas flow. When the nozzle is blocked or damaged, the gas flow will be uneven, resulting in unstable flames and sparks. Therefore, it is very important to clean and check the condition of the nozzle regularly.

3. Unstable gas pressure

During cutting, the pressure of the gas must remain stable. If the gas pressure fluctuates, the temperature and shape of the cutting flame will also change, which may cause sparks to fly. For example, too low oxygen pressure will lead to insufficient flame and incomplete combustion, while too low gas pressure may prevent the flame from maintaining its optimal state and produce sparks.

4. Electrical system failure

For some equipment using arc cutting, electrical system failure may also cause sparks. If there is a problem with the ignition circuit of the cutting machine or the grounding is poor, it will cause the arc to be unstable or short-circuited, and then sparks will occur. Therefore, the inspection and maintenance of the electrical system is also an important part of preventing sparks.

5. Improper operation

Improper cutting operation technique is also one of the causes of sparks. For example, if the operator cuts at an inappropriate angle or cuts too fast or too slow, the flame may be unstable and sparks may fly. In addition, different materials have different cutting requirements, and choosing inappropriate gas or cutting methods may also increase the risk of sparks.

How to prevent and solve

1. Adjust the gas ratio: Ensure that the ratio of oxygen to gas is reasonable, and make appropriate adjustments according to different cutting requirements to keep the flame stable.

2. Check the nozzle regularly: Keep the nozzle clean and intact, check the nozzle regularly for blockage, wear or contamination, and clean or replace it in time.

3. Keep the gas pressure stable: Check the pressure gauge of the gas equipment to ensure that the pressure of oxygen and gas is stable to avoid fluctuations affecting the cutting effect.

4. Check the electrical system: Regularly check the grounding, ignition circuit and other important components of the electrical system to ensure its normal operation.

5. Improve operating skills: Improve the professional skills of operators through training to ensure that operations such as cutting angles and speeds meet process requirements, thereby avoiding unnecessary sparks.

Huawei Laser reminds you: Although sparks from gas nozzles are normal in some cases during the cutting process, frequent occurrences may indicate equipment problems or improper operation. Through scientific operating specifications, regular equipment inspections and timely maintenance, sparks can be effectively prevented and the safety and efficiency of the cutting process can be ensured.