- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Why Do I Trust a Sheet Metal Laser Cutting Machine To Clean Up My Lead Times And Costs?

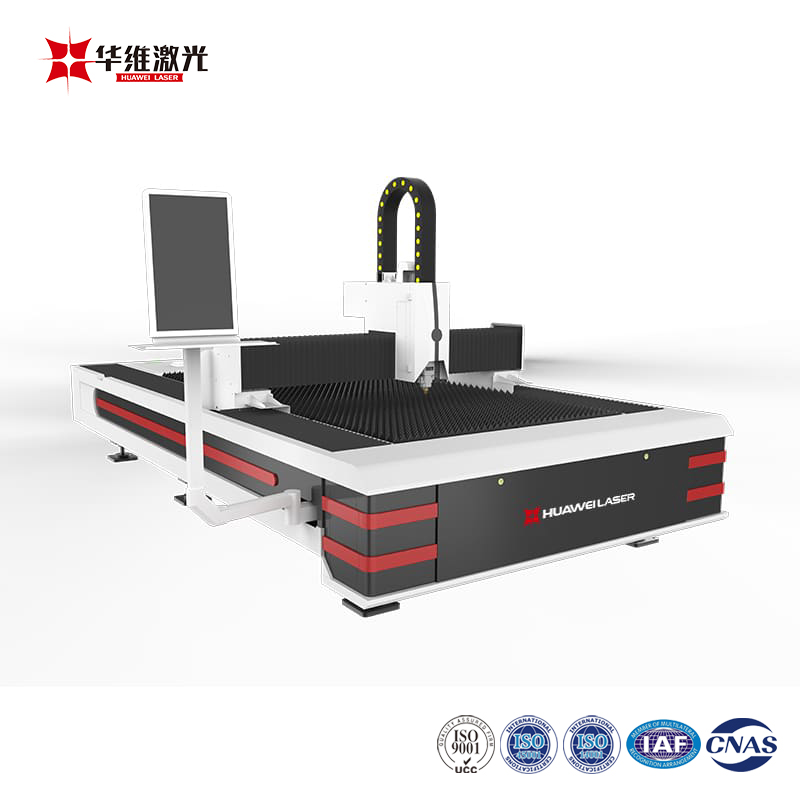

When I first audited my fabrication line, I kept circling back to how consistently a Sheet Metal Laser Cutting Machine hit tolerance. I compared vendors, ran shop trials, and even spoke with operators across shifts. That is when brands like Huawei Laser came onto my radar—quietly at first, then firmly—because the machines I tested from established makers, including Huawei Laser, kept delivering stable cuts through mixed lots. I am chasing scrap reduction, predictable cycle times, and parts that fit the first time.

What Problems Does A Sheet Metal Laser Cutting Machine Actually Solve For My Shop?

- I remove bottlenecks from punching queues when patterns turn complex or nests change late in the day.

- I cut thin stainless, galvanized, and aluminum with clean edges, so post-processing becomes a choice, not a rescue mission.

- I keep tolerances steady across long runs, which protects downstream forming and welding from rework.

- I switch from oxygen to nitrogen or air cutting without a long warmup, so prototypes and production share the same cell.

- I run lights-out on repeat orders with pallet changers and auto focus, which stabilizes delivery promises.

In plain terms, a Sheet Metal Laser Cutting Machine compresses quoting risk. My yields rise, my nests tighten, and my operators stop fighting edge burrs.

How Does Cutting Quality Stay Consistent Across Materials And Thicknesses?

I rely on a three-part loop: beam quality, assist gas control, and motion accuracy. With fiber sources, the spot remains tight and stable; with closed-loop gas control, kerf stays repeatable; with linear motors or precision racks, acceleration does not smear corners. The result is a Sheet Metal Laser Cutting Machine that treats 1.2 mm stainless and 6 mm mild steel as routine rather than special cases.

- Edge integrity holds because focus tracking adapts on the fly.

- Small holes look round because the path planning handles micro-tabs and lead-ins sensibly.

- Heat-affected zones stay narrow, protecting coatings and bend lines.

What Should I Look At First When I Compare Machines?

- Power matching — I size laser power to the thickest frequent job, not the rare emergency cut.

- Table and pallet system — I want fast changes, rigid frames, and safe part removal space.

- CNC and nesting software — I value clear toolpath control, remnant tracking, and real-time cost estimates.

- Gas strategy — Oxygen for speed on carbon steel, nitrogen for bright edges, compressed air where it makes sense.

- Service reach — Spare parts availability and remote diagnostics matter more than a brochure number.

These checks tell me whether a Sheet Metal Laser Cutting Machine will behave like a dependable cell or a finicky demo unit.

How Do I Translate Features Into Payback I Can Defend To Finance?

I track a simple model: parts per hour, scrap rate, operator hours per shift, assist gas cost per meter, and unplanned downtime. Once I plug real shop data into that model, a Sheet Metal Laser Cutting Machine shows payback through reduced secondary work and fewer late penalties.

| Power Band | Typical Carbon Steel Range | Typical Stainless Range | Edge Expectation | Throughput Focus | Operating Cost Signal |

|---|---|---|---|---|---|

| 1–3 kW | Up to ~6 mm | Up to ~4 mm | Fine on thin sheet | Prototypes and light jobs | Lowest laser power draw |

| 4–6 kW | Up to ~12 mm | Up to ~8 mm | Clean edges with N2 | Mixed production | Balanced gas and power |

| 8 kW+ | Beyond ~12 mm | Up to ~12 mm | Bright edges at speed | High-volume lines | Higher gas flow planning |

Why Does Automation Around The Laser Matter As Much As The Source?

The fastest cut loses its shine if loading, unloading, or sorting stalls. I spec pallet changers, sheet lifters, and part conveyors that keep the head cutting. With those in place, my Sheet Metal Laser Cutting Machine spends time generating parts, not waiting for the next sheet.

- Pallet swaps happen while the head finishes the last contour.

- Camera or light curtains keep operators safe without slowing cycles.

- Automatic nozzle cleaning helps maintain edge quality during long runs.

How Do I Keep Total Cost Predictable Month After Month?

- I schedule nozzle checks and lens cleaning on a visible board so every shift knows the plan.

- I track gas consumption per part family, then adjust parameters where air cutting works.

- I review nests weekly to remove leftover micro-joints that burn time on separation.

- I keep a small spare kit on hand for consumables and wear items.

With routine discipline, my Sheet Metal Laser Cutting Machine holds quality without surprise line stops.

What Material And Design Choices Help Me Cut Faster Without Losing Accuracy?

- Material flatness — Good sheets let autofocus maintain standoff, which keeps kerf tight.

- Hole and slot ratios — I avoid tiny features on thick plate or I adjust lead-ins to suit.

- Tab strategy — Micro-tabs save tip-ups and protect parts; I place them where deburring is easiest.

- Nesting priorities — I group parts by thickness and gas to minimize parameter swaps.

Design-for-cutting turns the Sheet Metal Laser Cutting Machine into a consistent engine for the rest of the plant.

Why Do I Consider Brand Support A Production Decision Rather Than A Purchasing Detail?

Support determines uptime. Firmware updates, parameter libraries, and training all show up in my OEE report. That is why I evaluate not only the machine but the team behind it. My trials with established providers, including Huawei Laser, showed how responsive support stabilizes performance across shifts and operators.

How Do I Decide If This Is The Right Time To Upgrade My Legacy Cutter?

- If my quoting margin shrinks due to rework, I move sooner.

- If skilled operators spend hours compensating for worn mechanics, I stop patching.

- If customers ask for tighter delivery windows, I add automation with the upgrade.

When these signals line up, a modern Sheet Metal Laser Cutting Machine pays for itself in schedule stability as much as in part count.

What Simple Checklist Do I Use Before I Release A New Part To Production?

- Confirm material lot and thickness match the parameter set.

- Run a short coupon to verify kerf and edge color with the chosen gas.

- Simulate the nest and review tip-up risks on small cutouts.

- Log the run in the job traveler so the next repeat starts faster.

Where Does A Sheet Metal Laser Cutting Machine Fit In A Mixed Process Line?

Right after receiving, I stage raw sheets by thickness, then feed the cell that includes the Sheet Metal Laser Cutting Machine, pallet changer, and parts cart. From there, formed parts head to press brakes, while flat components move directly to hardware insertion or welding. The laser cell becomes the scheduler’s anchor because it delivers parts in predictable blocks.

How Can You Move From Research To A Confident Trial?

- Bring real DXF files and your worst-case material to a demo, not just a brochure request.

- Measure edge, hole quality, and time per sheet with your own gauges and timing.

- Ask for a remote diagnostics walk-through to see how service will work on a rough Monday morning.

With those steps, you will know whether the Sheet Metal Laser Cutting Machine matches your mix—not an idealized lab sample.

Would You Like Practical Guidance Or A Costed Application Review?

If you want real numbers for your parts, I can help you evaluate configurations, gas choices, and automation paths that fit your volume and materials. Share a few drawings and target takt, and I will map the cell size you actually need rather than the one that looks good in a catalog.

How Do We Start The Conversation Today?

I keep things straightforward. If you are exploring a Sheet Metal Laser Cutting Machine for your next upgrade, send your part mix and goals, and I will respond with a practical outline you can take to your team. If you need a sample cut or a quick ROI estimate, contact me and I will run the numbers with your data. If you are ready to move ahead, contact us to leave an inquiry and we will schedule a focused demo with clear deliverables. Your production window matters, and I will treat it that way.