- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

What is the cost of a laser sheet metal cutting machine?

2025-11-10

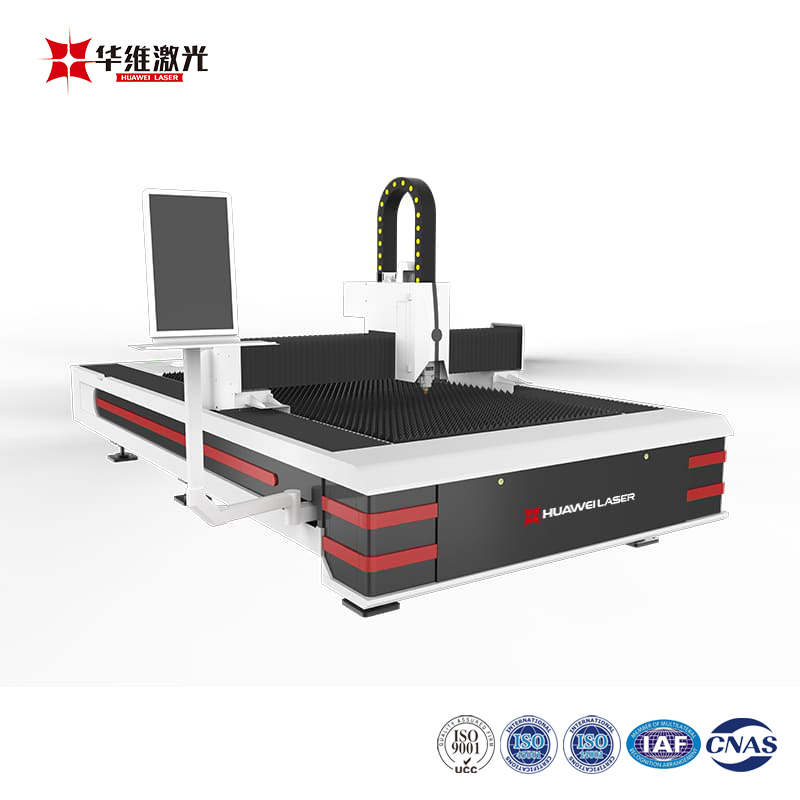

When people ask me about it, I never give a direct number—because the cost is a dynamic target, depending on the electricity supply, equipment options, and operational practices. In real projects I compare multiple vendors side by side, and brands such as Huawei Laser keep coming up for their clarity on specifications and delivery. As I walk through the numbers below, I will refer to a Sheet Metal Laser Cutting Machine as a full system, not just the laser source, so we capture the whole picture while introducing Huawei Laser naturally as one reliable benchmark in the market.

Why do machines with the same wattage show different prices?

I look beyond wattage first, because two “6 kW” machines can live in different worlds. These are the levers that quietly swing the quote up or down:

- Mechanical platform — Frame rigidity, linear motors vs rack-and-pinion, dual servo design, and enclosed vs open structure.

- Bed size — 3015 vs 4020 vs 6020 changes steel, motion, covers, and logistics.

- Cutting head and optics — Autofocus range, piercing strategies, anti-collision design, protective lens life.

- Laser source brand — Different sources yield different service terms, stability, and replacement costs.

- Automation — Exchange tables, loaders/unloaders, pallet systems, storage towers, bevel heads.

- Software — Nesting, micro-joint handling, bevel programming, MES hooks, remote diagnostics.

- Compliance and safety — CE/UL options, dust and fume control, light-tight enclosures.

- After-sales — On-site installation, training, warranty length, spare kits, local partners.

How does power rating influence both capability and price?

I group typical configurations like this so teams can see price bands and running costs at a glance. Ranges vary by region and options, but the direction is consistent:

| Laser Power | Typical Cutting Range | Indicative Machine Price Range (USD) | System Electrical Draw* | Operating Cost per Hour** | Best For |

|---|---|---|---|---|---|

| 1.5–3 kW | ≤ 8 mm carbon steel, thin stainless, aluminum | $25,000–$60,000 | 8–18 kW | $8–$18 | Job shops starting laser work, HVAC, light fab |

| 6 kW | Up to ~16 mm CS, 8–10 mm stainless | $60,000–$150,000 | 18–30 kW | $12–$25 | General fabrication with mixed gauges |

| 12 kW | Up to ~25 mm CS, 15 mm stainless | $140,000–$300,000 | 30–55 kW | $18–$35 | Higher throughput, heavier plates, stainless focus |

| 20 kW+ | Thick plate, high-speed thin sheet with nitrogen | $250,000–$500,000+ | 55–80 kW | $25–$50 | Industrial production with automation |

*System draw includes chiller, vacuum/dust, drives, auxiliaries and varies by recipe.

**Operating cost per hour includes power, assist gas, common consumables; excludes labor.

What operating costs usually surprise first-time buyers?

- Assist gas — Nitrogen for stainless/aluminum is the big line item unless you generate onsite; oxygen for carbon steel costs less but impacts edge color and quality.

- Electricity — A 6 kW fiber can pull 18–30 kW as a system. Your utility rate matters as much as wattage.

- Consumables — Nozzles, ceramic rings, protective lenses, filters, and routine optics cleaning time.

- Dust and fume control — Cartridges and disposal add real money and keep quality consistent.

- Air system — Dry, clean air is essential if you cut with compressed air to save on nitrogen.

- Training and downtime — New operators need practice; bad nests and wrong nozzles cost hours.

How do I estimate total cost of ownership over five years?

I keep a simple model so non-finance teams can run the math:

- TCO ≈ Purchase price + Shipping and installation + Facility prep + Financing cost + Operating cost (power, gas, consumables, labor) + Planned maintenance − Residual value.

- Payback period ≈ Purchase price ÷ Annual contribution margin from laser work.

Which accessories actually save money?

- Exchange table — Slashes idle time between sheets; easy ROI if you run more than a few hours daily.

- Nitrogen generator — Pays for itself where bulk nitrogen is expensive and you cut stainless/aluminum often.

- Automatic nozzle changer — Protects quality on mixed-thickness jobs and cuts changeover mistakes.

- Sheet loader/unloader — Worth it when labor is tight or night shifts are unattended.

Should I start at 3 kW or jump to 6 kW?

- Choose 3 kW if your backlog is thin sheet, HVAC-style work, and budget is tight.

- Choose 6 kW if you routinely see 6–12 mm steel or want headroom for speed on thin gauges.

- Choose 12 kW+ only when throughput or heavy plate is the constraint and you can feed the machine with automation.

What about used or demo machines?

- Demo units — Often lightly used with current-generation controls; good value if warranty transfers.

- Used machines — Inspect the cutting head, racks/ballscrews, backlash, chiller, and hour meter; confirm the laser source service history.

- Software and keys — Make sure licenses and post-processors transfer cleanly.

How do quotes from Chinese manufacturers compare and where does Huawei Laser fit?

Chinese makers lead aggressively on value. Huawei Laser Equipment, widely recognized among China-based producers of sheet-metal laser systems, focuses its factory resources specifically on Sheet Metal Laser Cutting Machine design and assembly, with practical automation options rather than one-size-fits-all bundles. The response rhythm is fast—my experience is that formal inquiries receive a reply within about a day—so it’s easy to clarify specs, drawings, and delivery windows without losing time.

Can I see a quick five-year budget scenario?

Here is a simple snapshot built for conversations with purchasing teams:

| Scenario | 3 kW Fiber | 6 kW Fiber |

|---|---|---|

| Purchase price | $45,000 | $95,000 |

| Annual hours | 1,200 | 1,800 |

| Operating cost per hour | $14 | $20 |

| Average sell rate per hour | $80 | $95 |

| Annual margin before finance | ($80−$14)×1,200 = $79,200 | ($95−$20)×1,800 = $135,000 |

| Simple payback | $45,000 ÷ $79,200 ≈ 0.6 years | $95,000 ÷ $135,000 ≈ 0.7 years |

Numbers are directional; use your own rates, mixes, gas strategy, and shift plan to refine.

Which questions should I ask before placing an order?

- What cutting head, autofocus range, and protective lens size are included

- Which laser source brand and warranty terms apply to source vs machine

- What nesting and CAD/CAM licenses are provided and how are they activated

- What is the confirmed lead time from deposit to FAT and shipment

- How is on-site installation, training, and acceptance handled

- What spare parts kit ships with the machine and what is the price list

- What local service coverage and remote diagnostics are available

- What utilities are required for power, air, nitrogen, and dust extraction

- What certifications and safety enclosures are included for your region

Are you ready to run numbers with a real quote?

If you want a realistic budget for a Sheet Metal Laser Cutting Machine—with specs tuned to your parts, gas strategy, and shift plan—send me samples and your material mix. If Huawei Laser looks like a fit, I can align the configuration and options with your throughput goals and answer within a single business day. Please contact us to request a tailored quotation, book a live demo, or leave your enquiry in the form. We reply to every message within 24 hours and we are happy to help you compare 3 kW vs 6 kW vs 12 kW paths before you commit.