- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

How to Judge the Cutting Quality of Laser Cutting Machine?

2025-03-26

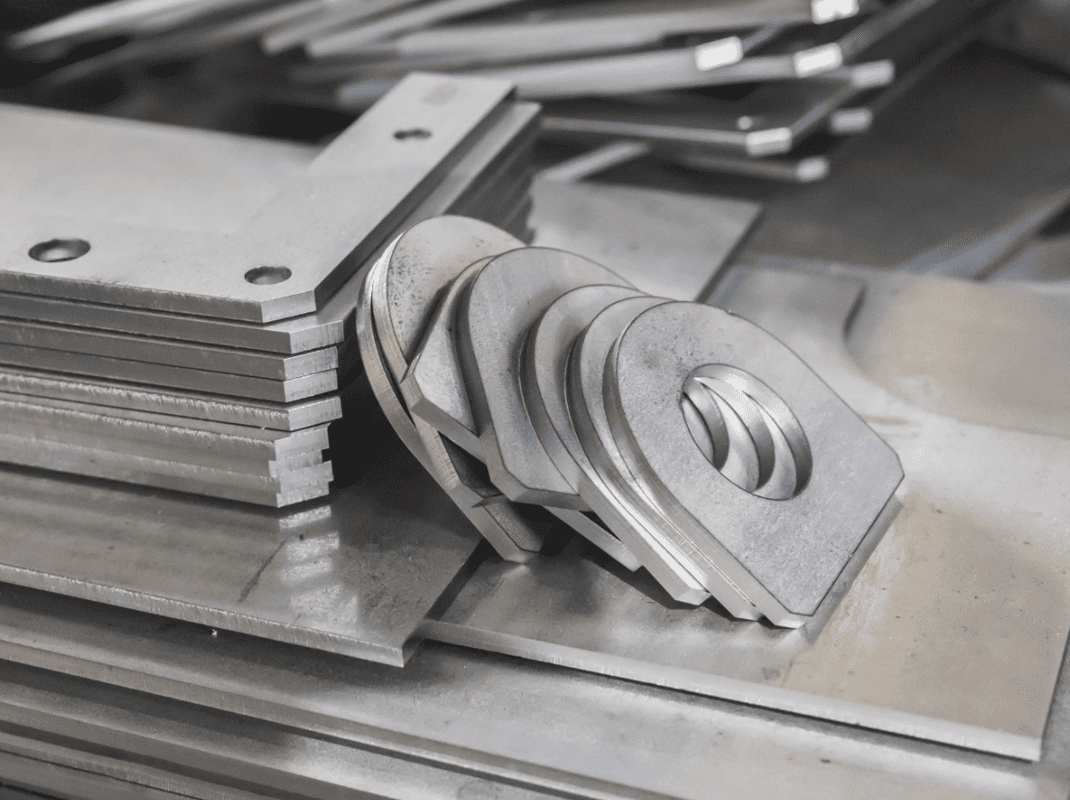

With the continuous upgrading of manufacturing industry, laser cutting technology has attracted wide attention due to its high precision, high efficiency and wide application fields. However, how to judge the cutting quality of laser cutting machine? This article will analyze it in detail for you.

1. Smoothness of cutting edge

The smoothness of cutting edge is an important indicator for judging cutting quality. High-quality laser cutting should have neat, smooth and burr-free edges. If the edge is rough or there is slag, it may mean that the laser power or cutting speed needs to be adjusted.

2. Verticality and geometric accuracy

For thicker materials, the verticality of cutting edge is particularly important. High-quality cutting should ensure that the cutting surface is perpendicular to the workpiece surface, otherwise it may affect the assembly accuracy of parts. In addition, whether the size of the workpiece meets the design requirements is also a key factor in measuring cutting quality.

3. Cutting slit width

The cutting slit width directly affects the accuracy of the workpiece. Generally speaking, narrower cutting slits mean higher accuracy, but the consistency of cutting slit width must be ensured, otherwise it may affect the final assembly.

4. Heat-affected zone

The heat-affected zone (HAZ) refers to the area where physical changes occur due to heat. High-quality laser cutting should minimize the heat-affected zone to avoid material deformation or performance degradation.

5. Cutting speed and slag situation

A reasonable cutting speed can reduce the generation of slag and ensure the smoothness of cutting. Too slow cutting speed may cause the material to overheat, while too fast speed may cause incomplete cutting. Therefore, it is crucial to choose the appropriate parameters.

6. Oxidation of the cutting surface

Different materials may produce an oxide layer during the laser cutting process. For workpieces that require subsequent welding or coating, the thickness and uniformity of the oxide layer are also important factors in evaluating the cutting quality.

Huawei Laser has always been committed to providing high-quality laser cutting equipment and technical support to help the manufacturing industry move towards higher precision and efficiency.

Choosing Huawei Laser means choosing excellent cutting quality and reliable technical guarantee.