- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Laser Cleaning : Ushering in a New Era of Industrial Rust Removal

2025-03-20

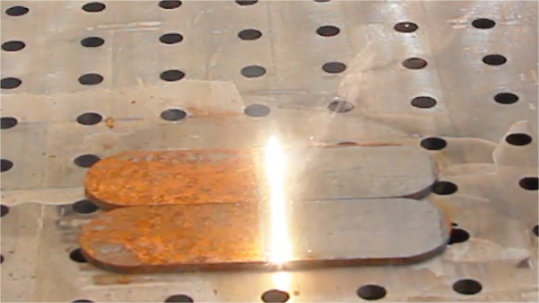

In recent years, laser cleaning technology has become an important innovation in metal surface treatment, thanks to its high efficiency, environmental friendliness, and non-destructive nature. It is now widely used in industries such as aerospace, automotive manufacturing, and ship restoration.

Principle of Laser Rust Removal

Laser rust removal utilizes a high-energy pulsed laser beam to irradiate the metal surface, causing the rust layer to absorb the energy and vaporize or detach, achieving a cleaning effect. Since the base material absorbs less of the specific laser wavelength, it remains undamaged. Additionally, the short pulse duration prevents heat buildup, ensuring precise cleaning.

High Efficiency and Environmental Friendliness

Traditional rust removal methods rely on chemical reagents or mechanical grinding, which pose risks of pollution and material damage. Laser cleaning eliminates the need for chemical agents and does not produce wastewater or solid waste. It meets environmental standards while effectively and precisely removing rust, improving cleaning efficiency.

Wide Applications

In the aerospace sector, laser cleaning removes oxidation layers from aircraft surfaces, enhancing maintenance efficiency. In automotive manufacturing, it is used for pre-weld treatment to improve weld quality. For ship restoration, laser rust removal efficiently removes corrosion from decks and hulls, enhancing the adhesion of protective coatings.

The demand for laser cleaning equipment is steadily increasing, with companies worldwide investing in research and development to enhance performance and reduce costs. Huawei Laser has introduced handheld laser cleaning machines, offering portability, operational flexibility, and high cleaning efficiency, making it suitable for various industrial applications.